Mahmoud Badawneh

Unconventional ideas often encounter initial resistance but ultimately become accepted truths. This is particularly evident in the construction industry, where many believe that construction processes differ fundamentally from manufacturing and cannot be managed like production lines.

Ford revolutionized the automobile industry by implementing assembly lines inspired by a butcher shop, despite facing skepticism. Meanwhile, Toyota challenged conventional practices and recognized the strategic advantages of Ford's methods, leading to the development of a significant automotive strategy known as Just In Time (JIT) delivery.

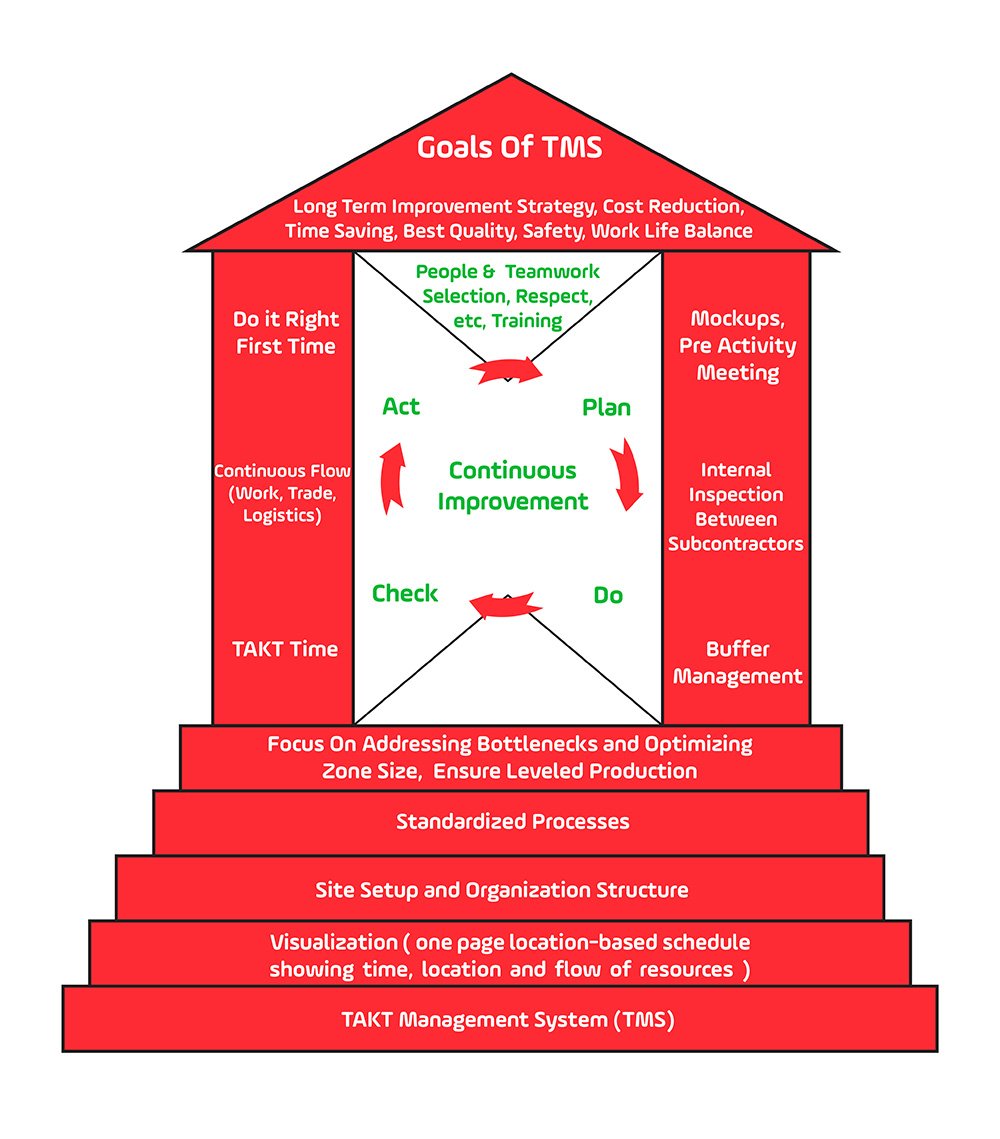

We should take a cue from Toyota by demonstrating that effective continuous improvement requires the integration of TAKT. Our goal is to promote TAKT methodologies globally, enhancing efficiency in construction projects. We aim to establish TAKT as a foundational element in creating a robust continuous improvement strategy.

Dr. Marco Binninger

What is TAKT ?

What is TAKT planning?

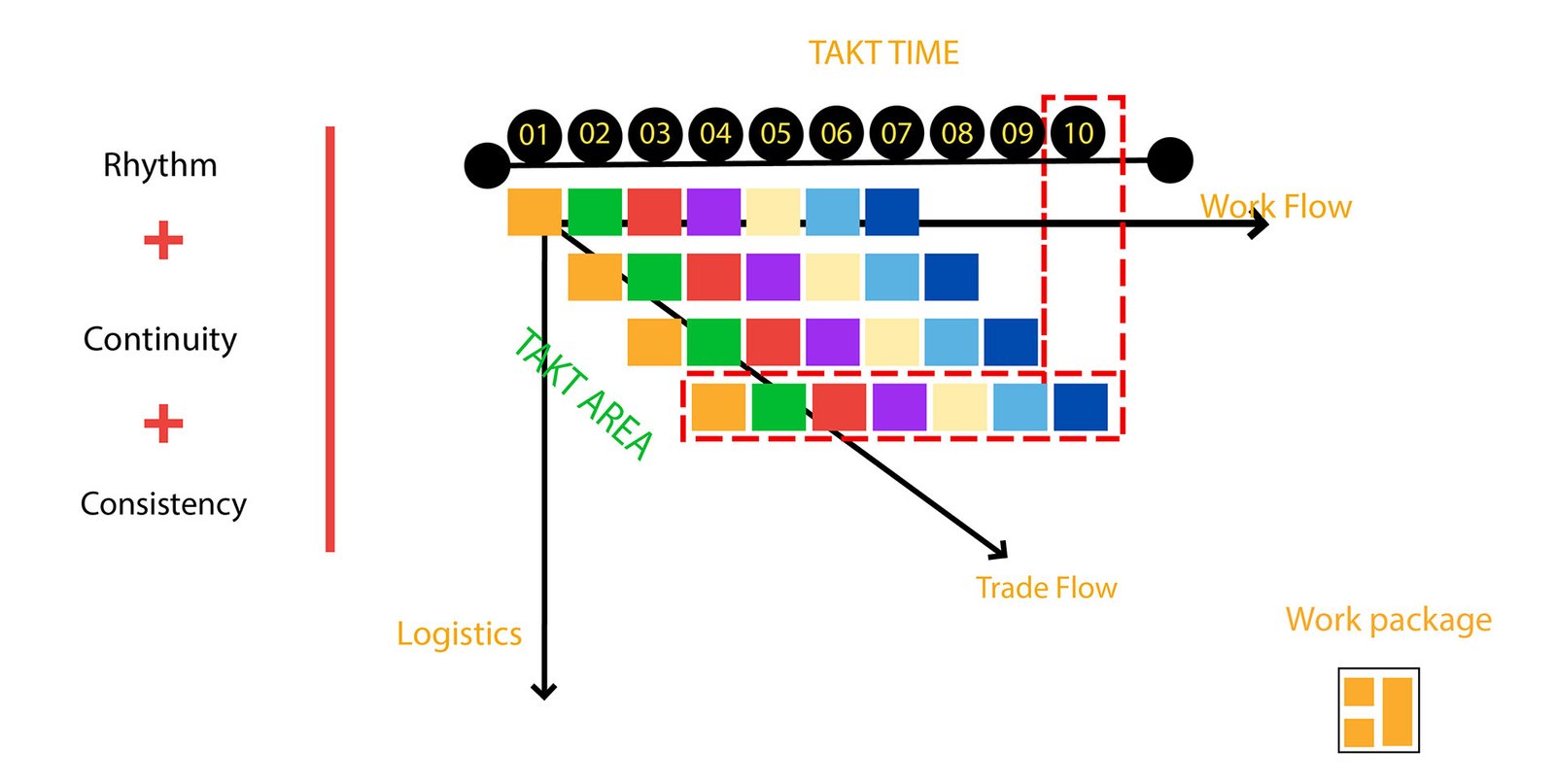

Takt planning is a detailed one-page location-based schedule (clearly show time and location), that shows all three types of flow through zones, workflow, trade flow and logistic flow. is scheduled with rhythm, continuity, and consistency

What is TAKT Time?

TAKT Management System

From TMS House the following services will be provided:

- TAKT planning

- Site setup evaluation and rearrangement

- Site operation processes preparation and implementation

- Construction team empowerment & transformation

- Field execution digitization